What is the use value of automatic paper bag machine with printing?

automatic paper bag machine with printing is a new generation of multi-layer kraft paper bag making machine designed to solve environmental pollution and comply with green environmental protection. It can be used for bag making of 70-140g kraft paper rolls. The machine is simple, convenient and quick to operate, and can produce folded bags, non-folded bags, single-layer packaging bags or multi-layer packaging paper bags of different bag types.

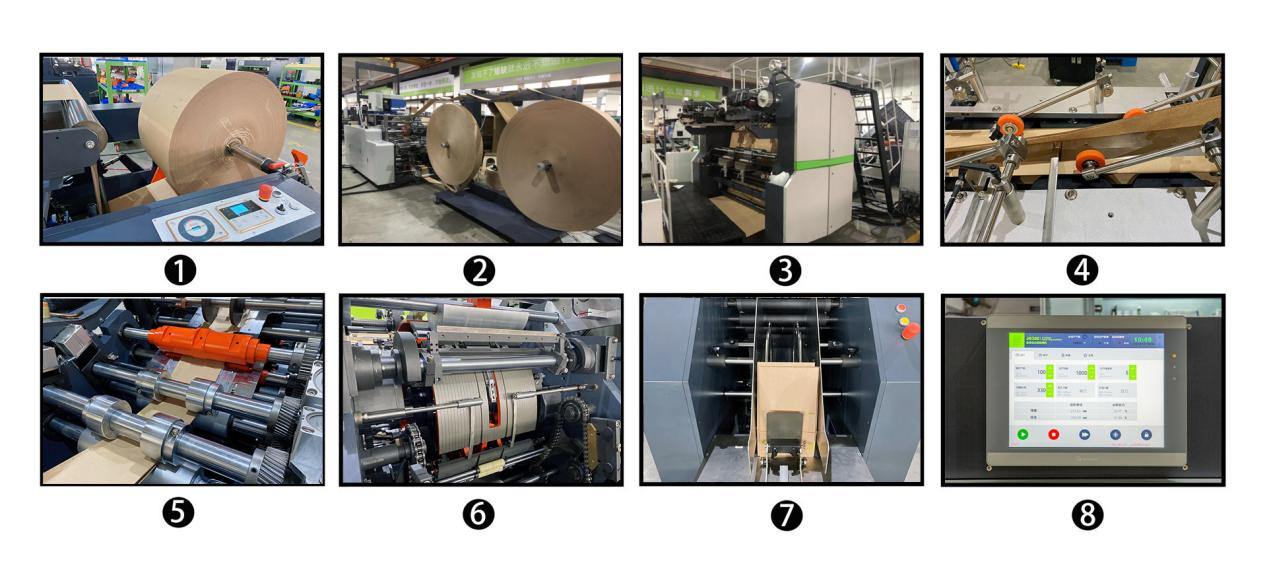

The unit is equipped with advanced electrical systems and mechanical devices throughout the process from substrate feeding, tube forming, edge gluing, bag cutting, and conveying and stacking bags, and adopts servo system combined with human-machine interface. The substrate is continuously completed from feeding to bag-making in one process flow, with a high degree of automation. With advanced bag-making technology, reasonable equipment structure, and beautiful and reliable tube bags, it is an ideal equipment for various bag-making enterprises at home and abroad to produce various types of packaging bags.

What is the scope of use of automatic paper bag machine with printing?

1. Applicable paper 30-100 grams

2. The length of the bag can be arbitrarily set within a certain range on the touch screen man-machine interface

3. PLC programmable servo control system

4. Accurate color mark tracking system

5. Automatic alarm and shutdown if the color code is wrong

6. Automatic lubrication oil supply system

What is the workflow of automatic paper bag machine with printing?

automatic paper bag machine with printing base material is continuously completed in one process flow from feeding material to finished bag making, with a high degree of automation. The bag-making technology is advanced, the equipment structure is reasonable, and the tube bag is beautiful and reliable. It is an ideal equipment for various bag-making enterprises at home and abroad to produce various types of packaging bags. This automatic food paper bag machine completes the folding, forming, bag cutting, gluing, bottom folding, bottom paste, and finished bag output at one time. , dry fruit bags and other environmentally friendly paper bags ideal equipment.