The RKFD-220 Square bottom paper bag machine is a highly appreciated machine in the paper bag manufacturing industry, specifically designed to produce high-quality square bottom bags. One of the most notable features of this machine is that it can produce up to 200 bags per minute. This high level of productivity makes it an ideal choice for businesses looking for an efficient and reliable paper bag-making machine.

Another excellent feature of the RKFD-220 Square bottom paper bag machine is its ability to produce bags with a square bottom. Square bottom bags are highly popular due to their ability to stand upright on their own. This feature provides businesses that use these bags with an excellent opportunity to advertise their brand since the bags provide a larger surface area for branding and product information.

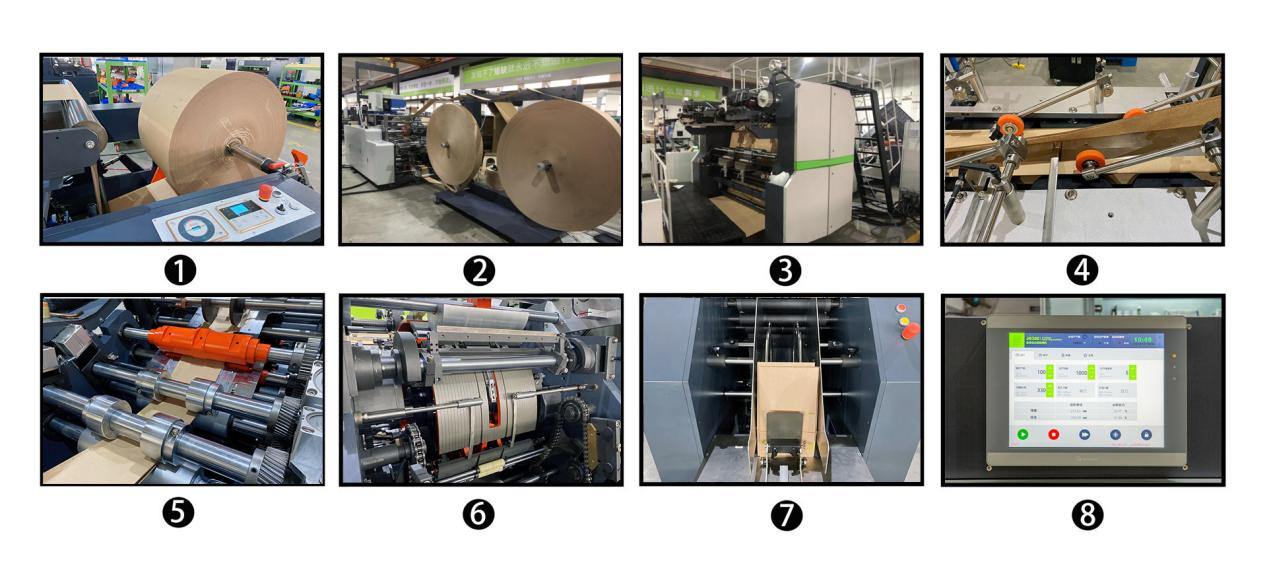

The RKFD-220 Square bottom paper bag machine revolutionizes paper bag production with its cutting-edge technology and superior performance. With its fully automatic operation and high precision, this machine ensures high production capacity while maintaining high quality standards. Its mechanical design guarantees high reliability and high safety during operation, making it an ideal choice for businesses seeking efficiency and peace of mind. Additionally, the machine offers multi-functionality, allowing customization such as custom logo printing and window paste to meet various packaging needs, from food packaging to shopping and beyond. Invest in the RKFD-220 to experience ecofriendly and biodegradable packaging solutions, aligning with modern sustainability trends.

In conclusion, the RKFD-220 Square bottom paper bag machine is an excellent choice for businesses looking to produce high-quality square bottom bags efficiently. It features a user-friendly interface, high productivity, and versatility, and is built to last. Moreover, the bags produced by this machine provide a larger surface area for branding and product information, improving brand visibility. If you're considering investing in a paper bag-making machine that delivers on all fronts, then the RKFD-220 Square bottom paper bag machine is an excellent choice.

Elevate your packaging game with the RKFD-220 Square bottom paper bag machine. Experience unparalleled efficiency, reliability, and customization options to meet your diverse packaging needs. Don't miss out on the opportunity to enhance your brand's visibility and contribute to a greener future. Order now and witness the transformation in your packaging operations!